Laser and water jet cutting are two of the fastest and most accurate ways of computer numerical controlled (CNC) cutting in the sheet metal fabrication industry. Both these cutting tools offer precision and flexibility, minimize waste and so are easily programmable with CAD/CAM or nesting software.

Both laser and water jet cutters have distinct advantages over a few of the more traditional cutting methods. They may be used with a variety of materials besides sheet metal, such as for example marble, glass, plastics and acrylic. Also, they are much more efficient than traditional machine tool cutting in terms of smaller orders that could be more specialized or require greater detail.

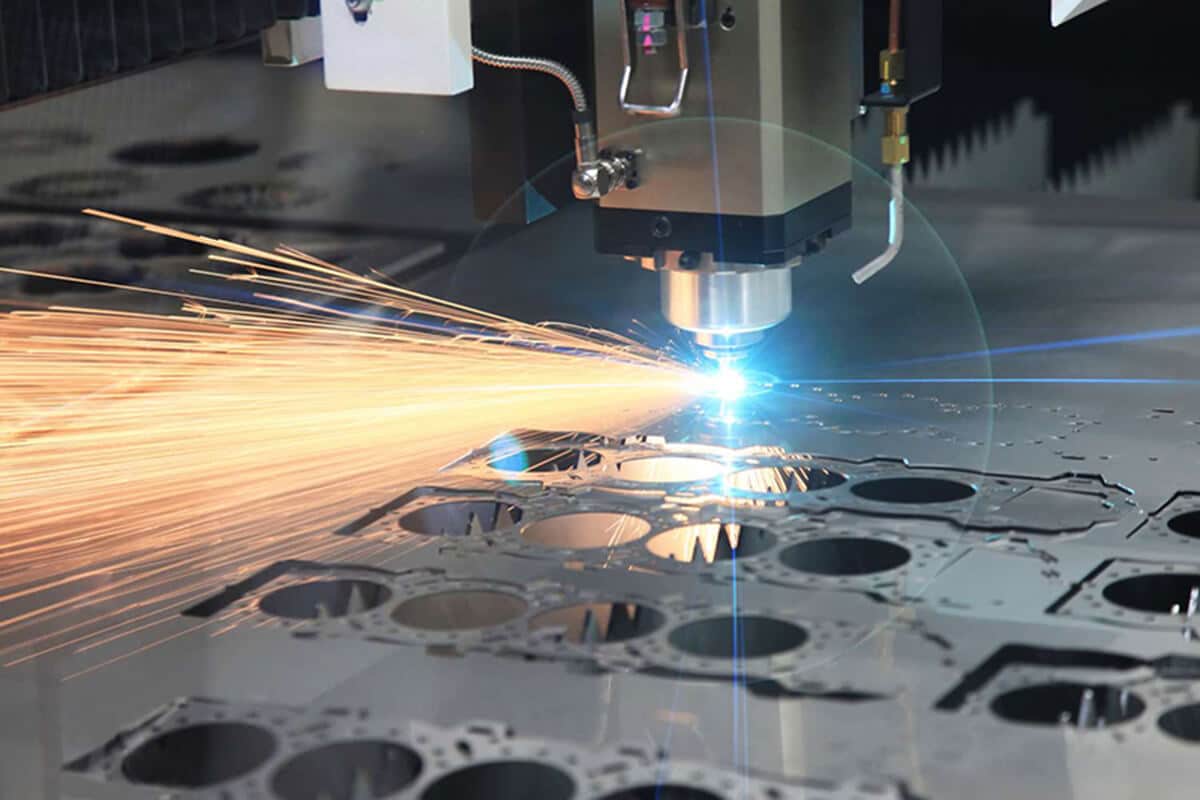

Laser Cutting

Fabrication software allows a programmer to input information which will direct a cutting tool to move along a design path with the purpose of cutting out a piece or part exactly as it was drawn up. There is absolutely no better tool for executing the precise cutting of a programmed pattern when compared to a laser cutting machine. When coupled with quality CNC laser software, lasers can perform very detailed cutting functions that include holes, slots and complex design patterns.

However, laser machines do have their limitations. When working with a laser cutter, the more wattage the deeper the cutting ability. Lasers are really quick and accurate when used to cut thinner metals. But when thicker metal can be used, "heat zones" can develop that will sometimes melt more sensitive metals or cause unevenness or rough spots in the material.

Therefore, laser cutting thicker metals is impractical not only because of possible damage to the material, but because it is more expensive. If heat zones or hot spots occur from overexposing the metal to the laser, extra work such as for example grinding the part could become necessary. This will increase labor and material expenses, in addition to the higher costs associated with more energy usage.

Water Jet Cutting

Although not as precise as laser cutting, water jet cutting has the ability to cut thicker material without causing damage. Considered an "abrasive" process, water jet cutting uses an abrasive material coupled with water in a highly concentrated stream to "erode" or break down the material being cut.

Though there may be some sanding or finishing involved after processing a piece, water jetting tools are a lot more acceptable to be used with thicker materials as well as the ones that are sensitive and vunerable to damage under extreme heat.

However, precautions must also be studied when cutting metal with a water jet tool. Visit website should be dried right away after cutting in order to avoid rusting. Also, since a cut from the water jet machine isn't as even or clean as when using a laser, the edges of the cut usually should be sanded or grinded. The piece should be "finished" so as to smooth it out and make it ready for possible welding.

Overall, both water jet cutting and laser cutting have their advantages. Water jet cutting is often more cost effective, but that also can depend on how big is the job and the thickness of the material being used. When applied to thinner, more detailed parts from sheet metal, a combination of top-line fabrication software and an excellent laser cutting machine may be the optimal scenario for producing quality parts quickly.